What is the Difference Between Rigid and Flexible PVC Conduit?

Categories:PVC Pipe and Fitting Author: author

In the world of electrical wiring and cable protection, PVC conduit systems offer safe, durable, and affordable solutions for a wide range of residential, commercial, and industrial applications. Among these systems, two primary types dominate the market: Rigid PVC Conduit and Flexible PVC Conduit. While both serve the purpose of protecting electrical wiring, their material properties, installation methods, and typical use cases differ significantly.

In this article, we will explore the key differences between rigid and flexible PVC conduit, their ideal applications, and the types of fittings they require. Additionally, we will list some frequently asked questions to help you make informed decisions for your electrical conduit installation.

What is PVC Conduit?

PVC conduit is a non-metallic tubing made from polyvinyl chloride (PVC), designed to encase and protect electrical wiring from physical damage, moisture, chemicals, and UV exposure. It is widely used due to its corrosion resistance, affordability, and ease of handling. The two most common forms are:

● Rigid PVC Conduit

● Flexible PVC Conduit

Rigid PVC Conduit: Structure and Uses

What is Rigid PVC Conduit?

Rigid PVC Conduit is a straight, inflexible pipe typically used for permanent wiring installations where long, straight runs are needed. It resembles a plumbing pipe and is usually available in Schedule 40 and Schedule 80 wall thicknesses.

Features of Rigid PVC Conduit

● Strong and impact-resistant

● Water-resistant and corrosion-resistant

● Lightweight and cost-effective

● Usually gray

● Suitable for direct burial and outdoor exposure

● Requires cutting and gluing during installation

SCH40 80 Electrical UPVC Rigid Conduit

Common Applications

● Underground electrical conduit

● Service entrance protection

● Outdoor lighting installations

● Industrial cable routing

● Agricultural and irrigation wiring systems

Rigid PVC Conduit Fittings

To complete a rigid PVC conduit system, a range of conduit fittings is required for bends, junctions, and connections. Common fittings include:

● PVC elbows (90°, 45°)

● Couplings

● Conduit bodies (LB, T, LL, LR)

● Adapters to connect to boxes or metallic systems

● Expansion couplings for outdoor applications with temperature variation

Most rigid PVC conduit fittings are joined using PVC solvent cement, which chemically welds the pieces together for a watertight and secure connection.

Flexible PVC Conduit: Structure and Uses

What is Flexible PVC Conduit?

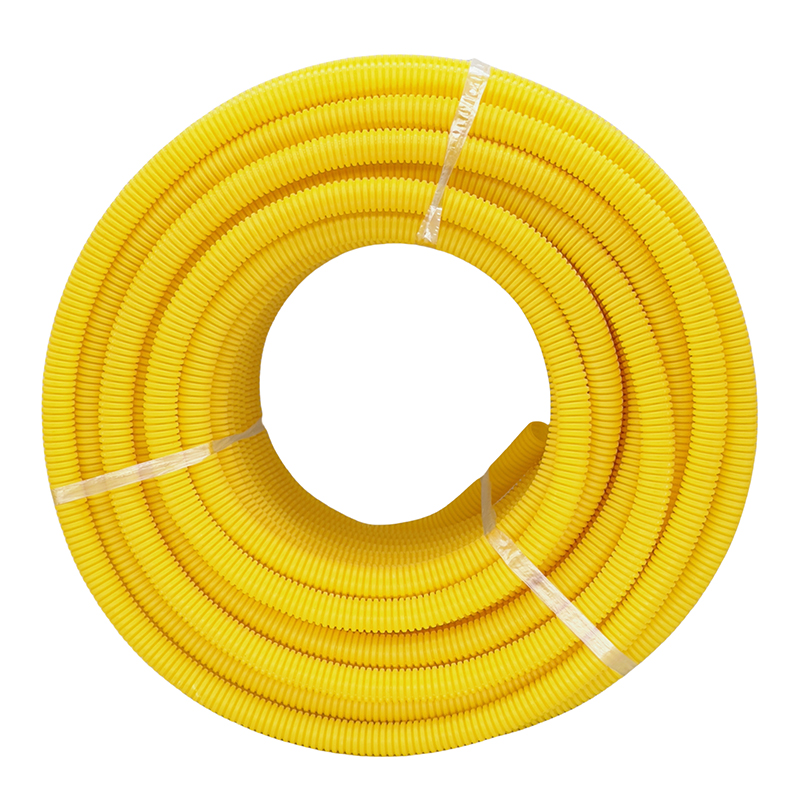

Flexible PVC Conduit, also known as PVC flex conduit, is a corrugated, bendable tubing ideal for short runs in confined or complex spaces. It is often used where wiring paths require frequent bending or maneuvering around obstructions.

Features of Flexible PVC Conduit

● Highly bendable without tools or heating

● Lightweight and easy to cut

● Moisture and oil resistant

● Designed for indoor use, or short-term outdoor use (with rated options)

● Suitable for dynamic environments (vibrations, movement)

Flexible PVC Conduit - TIS Corrugated Pipe

Common Applications

● Indoor wiring behind walls or ceilings

● Machinery and automation systems

● HVAC electrical connections

● Temporary cable protection

● Home renovations or retrofits

Flexible PVC Conduit Fittings

Unlike rigid systems, flexible conduit systems rely on compression or snap-lock flexible conduit fittings, including:

● Straight and 90° connectors

● Liquid-tight fittings

● Strain relief connectors

● Threaded adapters for electrical boxes

Flexible PVC conduit fittings do not require cement. Instead, they provide a tight mechanical seal, which simplifies installation and allows for future rework.

Comparison: Rigid vs. Flexible PVC Conduit

|

Feature |

Rigid PVC Conduit |

Flexible PVC Conduit |

|

Flexibility |

None |

High |

|

Mechanical Strength |

High |

Moderate |

|

Installation Speed |

Moderate |

Fast |

|

Suitable for Outdoor Use |

Yes |

Limited (unless rated) |

|

Ideal Applications |

Long runs, underground, exterior |

Short runs, indoors, tight spaces |

|

Joining Method |

Solvent cement and fittings |

Compression fittings |

|

Bending Requirement |

Heat or elbow fittings |

No tools required |

Rigid vs. Flexible PVC Conduit: When to Use Each Type?

Choosing the right PVC conduit type depends on your project requirements:

Choose Rigid PVC Conduit for:

● Outdoor or underground installations

● Areas requiring high mechanical protection

● Long, straight conduit runs

Choose Flexible PVC Conduit for:

● Indoor wiring with multiple bends

● Equipment connections with vibrations or movement

● Quick installations or temporary setups

In some complex systems, both types may be used in combination to optimize performance and flexibility.

Industry Usage Examples

● Construction projects: Rigid conduit is widely used in infrastructure and building foundations.

● Data centers and automation: Flexible conduit protects control wiring in movable machinery.

● DIY home wiring: Homeowners often use PVC flex conduit for renovations or garage lighting systems.

● Irrigation and solar projects: Rigid conduit routes power cables underground for pumps or solar inverters.

Frequently Asked Questions about Rigid and Flexible PVC Conduit

Can rigid and flexible PVC conduit be used together?

Yes. They can be connected using appropriate transition fittings. For example, you can terminate a rigid PVC run into an electrical box and then connect a flexible conduit to serve equipment or tight space layouts.

Is flexible PVC conduit waterproof?

Not all types. Standard flexible PVC conduit is moisture-resistant but not fully waterproof. For wet or outdoor environments, choose a liquid-tight flexible conduit designed specifically for such conditions.

Can flexible PVC conduit be buried underground?

Typically no, unless it’s rated for direct burial. For most underground wiring projects, rigid PVC conduit is preferred due to its strength and weather resistance.

How do I secure PVC conduit to walls or surfaces?

Use appropriate conduit straps or clamps. For rigid conduit, support spacing is usually every 3 to 5 feet. Flexible conduit should be secured at each end and at key support points to prevent sagging.

What tools are needed to cut rigid and flexible PVC conduit?

Rigid PVC: Use a PVC pipe cutter, miter saw, or hacksaw.

Flexible PVC: Use a sharp utility knife or heavy-duty scissors.

Do I need glue or cement for flexible PVC conduit?

No. Flexible PVC conduit uses compression fittings or snap-lock connectors, which do not require solvent cement. Rigid PVC conduit, on the other hand, usually requires PVC solvent cement for watertight, permanent joints.

Can I use PVC conduit for outdoor applications?

Yes. Rigid PVC conduit is ideal for outdoor use and can withstand sunlight, moisture, and mechanical stress. Ensure the product is labeled UV-resistant if exposed to direct sunlight.

What diameter sizes are available for PVC conduit?

PVC conduit comes in various sizes, typically ranging from ½ inch to 4 inches or larger. Common sizes include ¾", 1", and 2", depending on the application and number of conductors required.

Is PVC conduit fire-resistant?

Most electrical-grade PVC conduit is flame-retardant and self-extinguishing, but it’s not suitable for high-temperature environments. Always check temperature ratings for your application.

Can I bend rigid PVC conduit?

Yes, but you’ll need a PVC conduit heater or hot box. Alternatively, you can use pre-fabricated elbows or conduit bends for quick turns.

What are common fittings used with PVC conduit?

For rigid PVC conduit: elbows, couplings, adapters, expansion fittings, conduit bodies (LB, T, LL, LR).

For flexible conduit: straight connectors, 90-degree connectors, liquid-tight fittings, and strain relief fittings.

How do I choose between Schedule 40 and Schedule 80 PVC conduit?

Schedule 40 is suitable for general-purpose use.

Schedule 80 has thicker walls for high-impact or heavy-duty environments like industrial zones.

Does PVC conduit protect against rodents or insects?

Yes, to some extent. Rigid PVC offers good protection. For extreme rodent-prone environments, consider using metal conduit or installing barriers in addition to PVC.

Can flexible PVC conduit be reused?

Yes, if undamaged. Flexible PVC conduit is not glued and can be disconnected and reused in temporary or modular setups. Check the condition of both the conduit and fittings before reuse.

Can I run data or communication cables inside PVC conduit?

Yes, both power and low-voltage cables (such as network or coaxial) can be run through PVC conduit, provided separation guidelines are followed for safety and signal integrity.

Conclusion

Choosing between rigid and flexible PVC conduit depends on the specific needs of your electrical wiring project. Rigid conduit provides unmatched strength and is perfect for outdoor and underground installations, while flexible conduit offers versatility and ease of installation for indoor or confined spaces.

Each system requires different types of fittings, installation methods, and usage considerations. Understanding these differences can help you plan better, reduce installation time, and ensure long-term reliability. Whether you're working on a new building, upgrading an industrial system, or handling a home wiring task, selecting the right PVC conduit and fittings will ensure safe, efficient cable management.

If you are sourcing high-quality products, working with a reliable PVC conduit manufacturer who offers both rigid and flexible conduit solutions, as well as compatible fittings, can save you time and reduce complexity on the job site. ULP is one of your one-stop pipeline and accessory manufacturers, providing high-quality PVC rigid conduit, flexible conduits, and matching conduit fittings and accessories such as junction boxes, adaptable boxes, elbows, sweep bends, couplings, and more. Feel free to contact us for more.