Why Choose SCH 80 PVC Conduit for Industrial and Underground Use?

Categories:PVC Pipe and Fitting Author: author

In industrial and underground construction projects, the selection of conduit materials is a decision that directly impacts the safety, longevity, and overall performance of electrical systems. Among the many options available, Schedule 80 PVC conduit has gained popularity for its exceptional strength, durability, and cost-effectiveness.

Why does SCH 80 PVC conduit stand out in both industrial and underground applications? We'll delve into its technical advantages, typical use cases, compatibility with other components, and how it aligns with modern engineering standards. Whether you are an electrical contractor, engineer, or construction project manager, understanding the benefits of this conduit system can significantly streamline your project execution and maintenance.

Understanding SCH 80 PVC Conduit: What Makes It Unique?

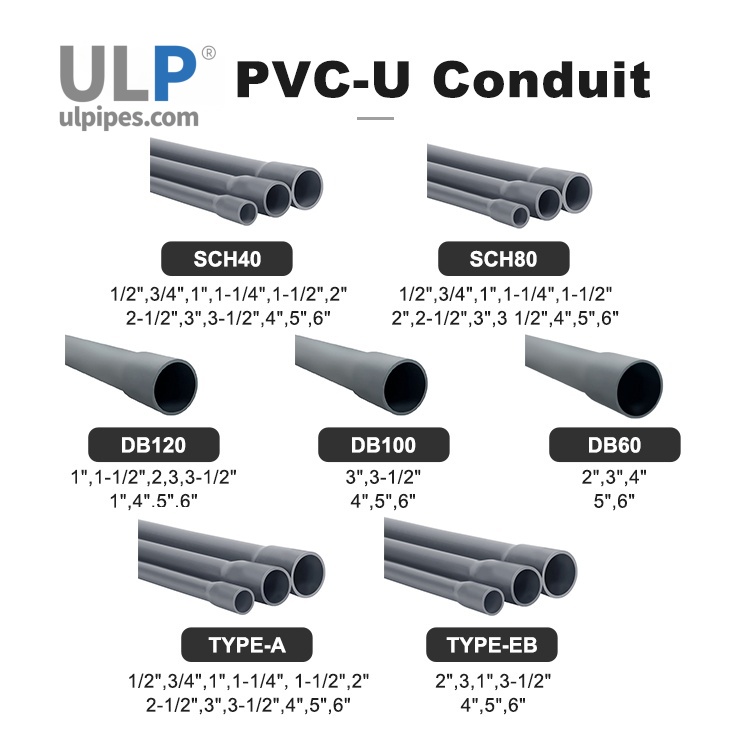

Schedule 80 PVC conduit, often abbreviated as SCH 80, refers to a type of polyvinyl chloride conduit with thicker walls than Schedule 40 PVC. While both are made from the same base material, SCH 80 is designed to withstand higher pressure and offer increased mechanical protection.

Key Features of SCH 80 PVC Conduit

Thicker Wall Design: SCH 80 has thicker walls than SCH 40, offering greater resistance to physical damage.

High Tensile and Impact Strength: Suitable for harsh environments where mechanical stress is a concern.

Corrosion Resistance: Unlike metal conduit systems, SCH 80 does not rust or corrode, making it ideal for chemically aggressive settings.

Non-Conductive Properties: Provides added safety in electrical installations by preventing unintended conduction.

Why Use SCH 80 PVC Conduit in Industrial Applications?

Industrial environments often expose electrical systems to high heat, moisture, physical stress, and chemicals. These conditions demand robust conduit solutions that protect electrical wiring while minimizing downtime and maintenance.

1. Enhanced Mechanical Protection

The thicker wall of SCH 80 PVC conduit offers excellent protection against physical impacts common in warehouses, processing plants, and manufacturing facilities. This robustness reduces the risk of crushing or cracking, thereby increasing the lifespan of the electrical system.

2. Chemical Resistance

In industrial applications involving acids, alkalis, or solvents—such as chemical plants or water treatment facilities—PVC conduit outperforms metal alternatives, which may corrode or degrade over time. SCH 80 PVC’s chemical resistance ensures long-term reliability without costly replacements.

3. Temperature Tolerance

While not ideal for extreme heat, SCH 80 PVC performs well within a wide temperature range. It's compatible with thermoplastic conduit fittings and PVC junction boxes, making it easier to build comprehensive electrical systems that meet code compliance.

4. Ease of Installation

Compared to metallic conduit, SCH 80 PVC is lightweight and easier to cut and join using solvent cement or mechanical fittings. This ease of handling significantly reduces labor time and installation costs.

Why Choose SCH 80 PVC Conduit for Underground Installations?

Underground electrical conduit must withstand soil pressure, moisture, and possible chemical exposure. SCH 80 PVC conduit meets these requirements while remaining cost-effective.

1. Structural Integrity Under Soil Load

The added wall thickness in SCH 80 provides superior resistance to crushing and deformation from soil weight or heavy equipment operating overhead, making it a preferred solution for direct burial conduit systems.

2. Moisture Resistance

PVC is inherently water-resistant, making SCH 80 an excellent choice for wet locations. It eliminates the risk of corrosion associated with galvanized steel conduit, ensuring underground electrical conduit systems remain safe and operational for years.

3. Compatibility with Concrete Encasement

For additional protection, SCH 80 PVC can be used in concrete-encased duct banks. This combination offers unmatched durability and is commonly specified in commercial electrical infrastructure and utility conduit systems.

Application Scenarios Where SCH 80 PVC Excels

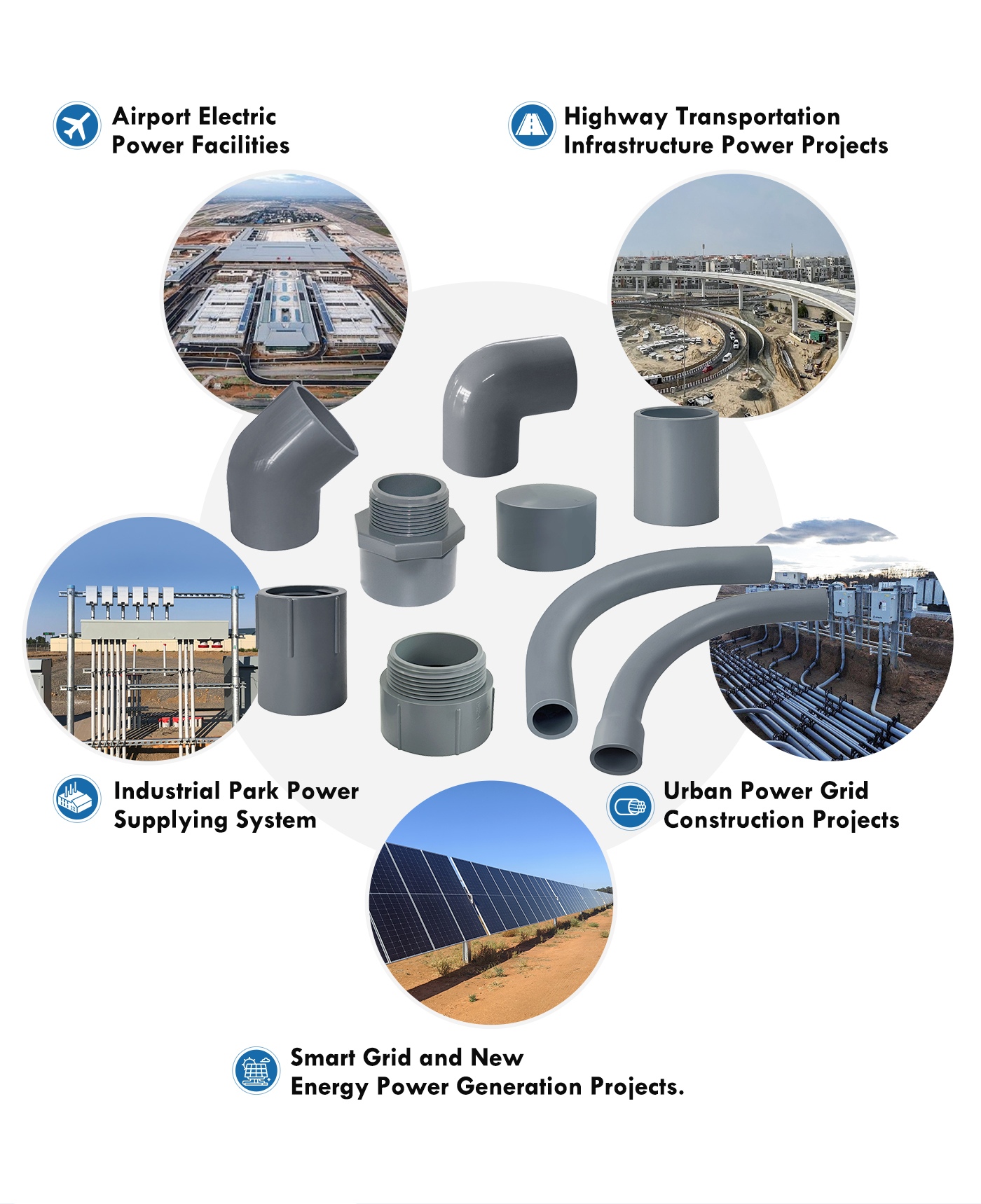

SCH 80 PVC conduit can be found in a wide range of industries and projects:

Data centers – require precise cable management, and protection is crucial.

Food processing plants – due to their resistance to washdown chemicals and ease of cleaning.

Power generation facilities – where electrical integrity must be maintained under mechanical and thermal stress.

Wastewater treatment plants – thanks to their chemical resistance and watertight properties.

Residential subdivisions – often used for underground utility conduit and service feeds.

Comparing SCH 80 PVC with Other Conduit Types

When selecting conduit for electrical systems, understanding the differences between various types is essential to match product characteristics with project requirements. Each conduit type offers distinct benefits and limitations based on its design, material properties, and intended use.

Below is a comparative overview of commonly used conduit types, including SCH 80 PVC, SCH 40 PVC, Electrical Metallic Tubing (EMT), and Rigid Metal Conduit (RMC):

|

Conduit Type |

Wall Thickness |

Corrosion Resistance |

Weight |

Installation Ease |

Typical Applications |

|

SCH 40 PVC |

Medium |

Excellent |

Light |

Easy |

Light-duty residential and commercial use |

|

SCH 80 PVC |

Thick |

Excellent |

Light |

Moderate |

Industrial, underground, or high-impact areas |

|

EMT (Metallic) |

Thin |

Low to Moderate |

Moderate |

Requires bending tools |

Indoor exposed conduit runs in dry settings |

|

Rigid Metal Conduit |

Thick |

Moderate |

Heavy |

Labor-intensive |

Outdoor, high-security, or fire-rated areas |

When compared to alternatives like EMT or rigid galvanized steel, Schedule 80 conduit offers a more efficient balance of durability, cost, and corrosion resistance for both above-ground and underground scenarios.

No single conduit type is universally superior. The best choice depends on the specific needs of your project, including environmental conditions, regulatory requirements, mechanical demands, and budget constraints.

Choosing the Right Manufacturer Matters

Not all SCH 80 conduit is created equal. It's critical to work with reliable PVC conduit manufacturers who offer consistent quality and support.

Recommended Features to Look For:

● Product tested to meet UL standards

● Available with bell end conduit for easy connection

● Broad size availability

● Comprehensive accessory support: elbows, junction boxes, fittings

● Good customer service and technical support

Top suppliers also provide engineering documentation, installation guides, and third-party testing results to support your project from design through installation.

Learn More about SCH 80 PVC Conduit with the Following FAQs

1. What is the difference between SCH 40 and SCH 80 PVC conduit?

The primary difference lies in wall thickness. SCH 80 PVC conduit has thicker walls than SCH 40, which gives it greater strength and pressure resistance. This makes SCH 80 more suitable for industrial environments and underground applications where mechanical protection is critical.

2. Is SCH 80 PVC conduit rated for underground use?

Yes, SCH 80 PVC conduit is commonly used in direct burial conduit systems and underground applications. It offers excellent resistance to moisture, soil pressure, and corrosion, making it ideal for protecting electrical wiring beneath the surface.

3. Can SCH 80 PVC conduit be used in exposed or outdoor installations?

Yes. While Schedule 80 PVC conduit is primarily known for underground and industrial applications, it can also be used in exposed environments, especially when UV-rated. However, UV resistance should be verified with the PVC conduit manufacturer or product specification.

4. Does SCH 80 PVC conduit require special fittings?

SCH 80 PVC conduit is compatible with standard PVC fittings, such as PVC junction boxes, bell end conduit, and thermoplastic conduit fittings. For optimal sealing and mechanical strength, use solvent cement specifically designed for PVC conduit systems.

5. Is SCH 80 PVC fire-rated or flame-retardant?

PVC conduit generally offers limited fire resistance. SCH 80 is not inherently flame-retardant, and it's important to consult local codes or product specifications if fire performance is a critical requirement. In such cases, alternatives like rigid metal conduit (RMC) may be recommended.

6. Can SCH 80 PVC conduit be used for high-voltage installations?

Yes, SCH 80 PVC is non-conductive and rated for many voltage levels used in commercial and industrial settings. However, always ensure the conduit system is designed to comply with National Electrical Code (NEC) guidelines and the voltage rating of the application.

7. Is SCH 80 PVC conduit resistant to chemicals and oils?

Yes, one of the main advantages of SCH 80 is its chemical resistance. It performs well in environments where oils, acids, or alkaline solutions are present, such as wastewater treatment plants or chemical processing facilities.

8. How is SCH 80 PVC conduit installed?

SCH 80 PVC can be installed using solvent welds, threaded fittings, or gasketed connections, depending on the system requirements. Its lightweight nature makes it easier to handle compared to metallic conduit, helping reduce labor costs.

9. Can SCH 80 PVC be encased in concrete?

Yes, SCH 80 is often specified in concrete-encased duct banks due to its mechanical strength and corrosion resistance. It is commonly used in utility conduit systems and commercial electrical infrastructure projects where additional protection is desired.

10. Who manufactures SCH 80 PVC conduit?

Reputable PVC conduit manufacturers are offering SCH 80 products that meet industrial standards. ULP is one of your ideal choices, we provide you with SCH 80 PVC conduit and fittings.

SCH 80 PVC Conduit Manufacturer

Conclusion: SCH 80 PVC Conduit Is the Smart Choice

In summary, SCH 80 PVC conduit is a highly dependable solution for both industrial and underground electrical applications. Its superior mechanical strength, corrosion resistance, and ease of installation make it a go-to option for engineers, contractors, and facility managers alike.

ULP is a complete one-stop pipeline and fittings manufacturer. Contact us for customized SCH80 PVC conduit and fittings. Whether you're installing power distribution in a heavy manufacturing plant or running underground feeds for a utility company, ULP SCH 80 PVC conduit delivers long-lasting performance and regulatory compliance, while helping you stay within budget.