DB60 vs. DB100 vs. DB120 PVC Conduit: Which PVC Conduit Is Best?

Categories:PVC Pipe and Fitting Author: author

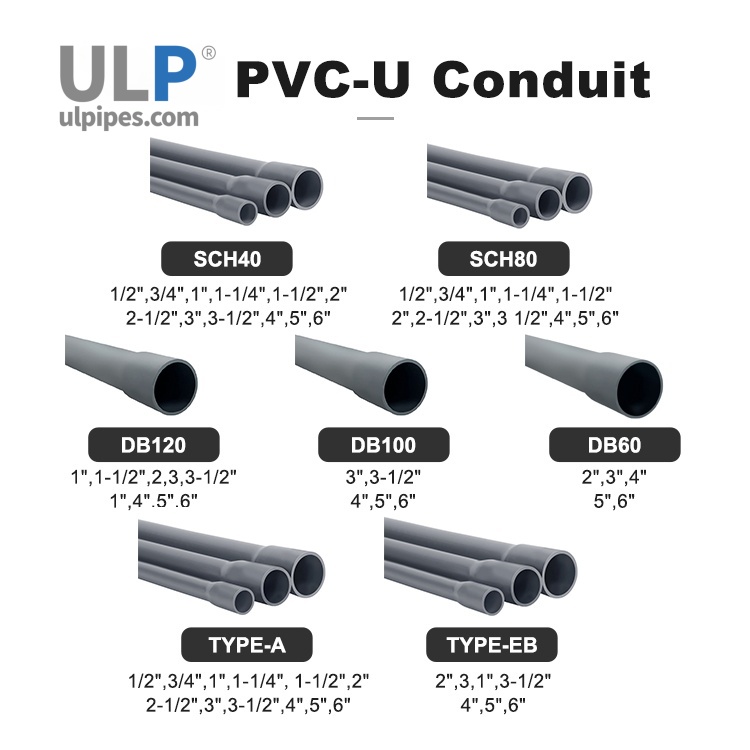

Selecting the correct PVC conduit is a crucial step in any electrical infrastructure project. Whether you’re working on underground utility distribution, data cabling, or telecom networks, using the right conduit type—DB60, DB100, or DB120—ensures long-term performance, safety, and compliance with local codes.

Each conduit type is specifically engineered to meet different performance criteria based on wall thickness, crush resistance, and environmental durability. In this guide, we’ll break down the differences between DB60, DB100, and DB120 conduits and help you choose the most suitable option for your project.

Understanding DB-Rated Conduit: What Do DB60, DB100, and DB120 Mean?

"DB" stands for "Direct Burial". Here’s a breakdown of each:

● DB60 PVC Conduit: Designed for direct burial applications, offering a balance of strength and cost-effectiveness for lighter-duty situations.

● DB100 PVC Conduit: Offers increased strength and is suitable for applications where more robust protection is needed compared to DB60, but may not be as heavy-duty as DB120.

● DB120 PVC Conduit: The most robust of the three, providing superior strength and resistance to damage from soil pressure, thermal expansion, and mechanical loads, making it ideal for deeper burial or areas with challenging conditions.

Each variant offers varying levels of mechanical protection, cost-effectiveness, and flexibility. The larger the number after DB, the stronger the catheter and the higher the price.

DB60 PVC Conduit: Economical for Light-Duty Underground Use

DB60 conduit is a popular choice for residential and light commercial installations. It’s designed for low-impact, shallow burial projects where minimal load stress is expected.

Key Applications

● Residential electrical service lines

● Landscape lighting systems

● Shallow-depth irrigation control wiring

● Fiber optic cable conduit for small installations

Pros

● Lightweight and easy to install

● Cost-effective for large-scale residential developments

● Compatible with standard solvent-weld fittings

DB100 PVC Conduit: The Versatile Mid-Grade Choice

The DB100 conduit offers a balanced performance-to-cost ratio, making it ideal for commercial projects and moderate-load conditions. It is the most commonly used type in utility-grade underground conduit systems.

Key Applications

● Commercial buildings’ electrical distribution systems

● Secondary utility service conduits

● Municipal traffic light wiring

● Solar farm underground cabling

Advantages

● Higher crush resistance

● Durable in a range of soil and weather conditions

● More rigid than DB60, but still relatively easy to handle

Best Use Scenarios

DB100 is particularly valuable in solar infrastructure design, where cable protection over long distances is necessary but without the weight constraints of DB120. It's also widely recommended in telecom conduit system layouts for fiber deployment. When selecting a PVC conduit for utility installations, many project engineers choose DB100 as the default unless extreme load or depth requires a stronger solution.

DB120 PVC Conduit: Engineered for Maximum Protection

For industrial or municipal applications requiring the highest durability, DB120 conduit is the industry standard. With a crush resistance rating, it withstands extreme pressure from soil compaction, heavy machinery, and deep burial.

Key Applications

● Roadway and airport lighting conduit systems

● Industrial facility service conduits

● Utility corridors under major highways

● Telecommunications backbone in metropolitan areas

Strengths

● Meets the highest durability requirements for underground PVC conduit

● Ideal for long-term infrastructure with limited accessibility

● Common in high-traffic zones or where future excavation is unlikely

DB120 is often specified in public infrastructure conduit specifications and used by conduit suppliers serving heavy-duty applications.

How to Choose Between DB60, DB100, and DB120 PVC Conduit?

Choosing the right PVC conduit depends on project requirements, site conditions, and regulatory codes. Here's a practical decision-making guide:

|

Criteria |

DB60 |

DB100 |

DB120 |

|

Load Resistance |

Light-duty |

Medium-duty |

Heavy-duty |

|

Ideal Installation Depth |

Shallow |

Moderate |

Deep |

|

Traffic Exposure |

Pedestrian or landscaping only |

Occasional light vehicles |

Heavy vehicles, industrial or municipal areas |

|

Application Type |

Residential, garden lighting |

Commercial, telecom, solar farms |

Highways, airports, utility infrastructure |

|

Budget Considerations |

Most affordable |

Balanced cost and performance |

Higher cost, best protection |

|

Code Compliance Areas |

Low-risk zones |

Standard commercial areas |

Regulated high-impact zones |

If your project involves a critical power grid, deep burial, or heavy construction traffic, DB120 is the clear choice. For general commercial use, DB100 strikes the best balance. Meanwhile, DB60 remains suitable for cost-friendly, light-use environments. For added assurance, consult with a PVC conduit supplier or electrical engineer familiar with your local utility standards.

Sourcing Quality PVC Conduit

When sourcing DB-rated PVC conduit, it’s essential to partner with reliable conduit manufacturers and distributors that meet or exceed standards.

Leading Features to Look For:

● Uniform wall thickness

● Certification stamps

● UV stabilization (if temporarily exposed)

● Smooth inner surface for easy cable pulling

Some leading electrical PVC conduit manufacturers offer pre-lubricated DB120 options for reduced friction and faster cable installation.

Conclusion: Trust ULP for Complete Conduit Solutions

Choosing the appropriate conduit—DB60, DB100, or DB120—is foundational to the safety and longevity of any underground electrical or communication system. While each conduit type serves a distinct purpose, working with a reliable supplier ensures your investment delivers long-term value.

ULP is a trusted PVC conduit manufacturer with proven expertise in PVC conduit and fittings. ULP provides all three conduit types—DB60, DB100, and DB120. In addition, ULP offers customized conduit solutions tailored to specific project needs, including specialized lengths, sizes, and color coding.

|

Raw material |

PVC |

|

Standards |

UL651 |

|

Dimensions |

According to the product |

|

Color |

Grey or customized to suit your project needs |

|

Application |

Underground and above construction |

|

Feature |

Character-flame resistant, UV resistant, corrosion resistant, etc |

|

Custom made |

Flexible OEM/ODM-size, colors, and packaging can be customized |

|

Tensile strength |

5,000 psi (3.45 KN/cm²) |

|

Extrusion |

Fusion |

|

Water absorption |

﹤0.50% of the whole weight after soaking |

|

Resistance to crushing |

ID≥70% after the test |

|

Resistance to impact |

Less than 3 of 1/32 inch cracks & tears |

|

Deflection under load |

﹤0.25mm deformation |

|

Fire rating |

UL 94V-0 |

|

Resistance to specific reagents |

Less ±2.50% weight after 60 / 120 days soak |

|

Permanency of printing |

Yes |

|

Rust & sunlight Resistant |

Yes |

|

Shipping |

By sea |

|

Samples |

Available |

From residential developments to high-impact industrial installations, ULP conduit systems offer performance, compliance, and durability. Partnering with ULP ensures your next project is built on a solid foundation.