Electrical Conduit vs. Plumbing Pipe: A Complete Guide for Builders

Categories:PVC Pipe and Fitting Author: author

When tackling any building project—be it residential, commercial, or industrial—understanding the systems hidden behind walls, floors, and ceilings is essential. Two of the most fundamental systems are the electrical conduit system and the plumbing pipe network. At first glance, they may seem similar: both involve tubes and fittings running throughout the structure. However, their functions, materials, codes, and installation requirements are vastly different.

For builders, contractors, engineers, and MEP designers, making the right choice between conduit and pipe is not just about compliance—it's about safety, efficiency, long-term performance, and cost-effectiveness.

What Are Electrical Conduits and Plumbing Pipes?

Electrical Conduit

An electrical conduit is a tube used to encase and protect electrical wires and cables from mechanical damage, moisture, and corrosive elements. In commercial and industrial construction, conduits are indispensable in areas where wiring must be shielded from impact or chemical exposure.

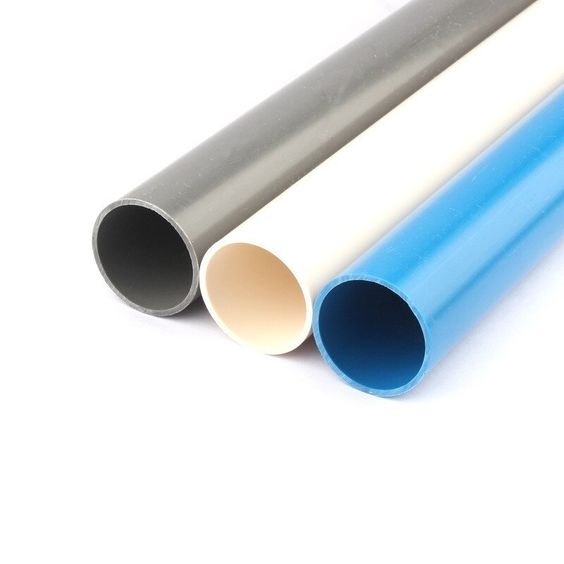

There are several types of electrical conduits:

● Rigid Metal Conduit (RMC)

● Electrical Metallic Tubing (EMT)

● PVC electrical conduit

● Flexible Metal Conduit (FMC)

● Liquid-Tight Flexible Non-Metallic Conduit (LFNC)

Each serves a unique purpose, with varying levels of durability, flexibility, and installation complexity.

Schedule 40 80 Electrical UPVC Rigid Conduit

Plumbing Pipe

Plumbing pipes are systems of tubes that transport fluids—including potable water, wastewater, gas, and chemicals—within a building. The design and material selection must support the specific pressure, temperature, and flow requirements of the application.

Common types of plumbing pipes include:

● PEX pipe systems for flexible, modern water distribution

● CPVC and PVC pipes for hot/cold water supply

● Copper pipes for high durability and corrosion resistance

● ABS and cast iron pipes for waste and drainage

Core Differences Between Conduit and Pipe

|

Feature |

Electrical Conduit |

Plumbing Pipe |

|

Primary Purpose |

Protect electrical wiring |

Transport fluids (water, gas, waste) |

|

Pressure Rating |

None (not designed for fluid flow) |

Rated for pressure and temperature |

|

Governing Code |

NEC (National Electrical Code) |

IPC / UPC (Plumbing Codes) |

|

Material Options |

PVC, steel, aluminum, flexible metal |

PEX, PVC, CPVC, copper, cast iron |

|

Safety Certifications |

UL-listed |

NSF-certified |

|

Tools Required |

Conduit benders, fish tape |

Crimp tools, solder, PEX expander |

|

Maintenance Needs |

Low if properly installed |

Moderate (subject to scaling, leaks) |

Key Materials and Their Performance

Electrical Conduit Materials

● PVC Conduit: Lightweight, corrosion-resistant, and ideal for underground or wet locations. Not to be confused with plumbing PVC.

● EMT (Electrical Metallic Tubing): Economical, commonly used in commercial buildings. It’s thin-walled but durable.

● RMC: Heavy-duty rigid steel conduit, ideal for outdoor or industrial use.

● FMC & LFMC: Provide flexibility for tight spaces, often used for temporary wiring or connections to equipment.

Plumbing Pipe Materials

● PEX Pipe Systems: Gaining popularity in new construction due to low cost, ease of use, and flexibility.

● PVC and CPVC Plumbing Pipe: Suitable for cold and hot water systems; CPVC has higher temperature resistance.

● Copper Pipes: Durable, bacteria-resistant, and traditional in high-end or long-term builds.

● Cast Iron and ABS: Used in DWV (drain, waste, and vent) systems for noise reduction and structural integrity.

Code Compliance and Safety Standards

Electrical Standards

The National Electrical Code (NEC) provides detailed specifications on:

● Conduit fill percentage

● Grounding requirements

● Protection against physical damage

● Conduit support spacing

Only UL-listed electrical conduit can be used in code-compliant installations.

Plumbing Standards

Plumbing installations are regulated by the International Plumbing Code (IPC) or the Uniform Plumbing Code (UPC). These codes focus on:

● Water quality (e.g., NSF-certified piping)

● Pressure ratings

● Thermal resistance

● Sanitary drainage

Improper use of materials or fittings can result in fines, failed inspections, or worse, system failures that cause flooding or contamination.

How to Choose Electrical Conduit?

Selecting the right electrical conduit depends on several factors, including the environment, installation method, code requirements, and project type. Here’s a practical guide for choosing the right conduit:

● Indoor Dry Locations: Use EMT (Electrical Metallic Tubing) for cost-effective and easy-to-bend installations in commercial buildings.

● Outdoor or Corrosive Environments: Go for PVC conduit or RMC (Rigid Metal Conduit) with weatherproof coatings.

● Tight Spaces or Moving Equipment: Opt for Flexible Metal Conduit (FMC) or Liquid-Tight Flexible Non-Metallic Conduit (LFNC) for ease of routing.

● Underground Installations: Choose Schedule 40 or Schedule 80 PVC conduit rated for burial.

● High Fire-Rated Applications: Use metallic conduit systems such as RMC, which offer enhanced fire protection.

How to Choose Plumbing Pipe?

Choosing the right plumbing pipe starts with identifying the fluid type, pressure, temperature, and whether the application is residential, commercial, or industrial:

● Potable Water Supply: Use PEX-A pipe systems or CPVC plumbing pipe, which are durable, easy to install, and corrosion-resistant.

● Hot Water Lines: Choose CPVC or copper pipe, both known for their temperature resistance.

● Drainage or Waste Systems (DWV): Go with ABS or cast iron for structural soundproofing and stability.

● Outdoor or UV-Exposed Installations: Use UV-rated PEX or PVC, and avoid indoor-grade pipes outdoors.

● Quick Installation Needs: Consider push-to-connect fittings with PEX systems to minimize labor and tools.

Installation Techniques and Tools

Electrical Conduit Installation

Electrical conduit requires:

● Conduit benders for EMT and RMC

● Fish tape or wire pullers to feed wiring

● Secure straps and hangers

● Solvent welding (for PVC), threading (for RMC), or compression fittings

It demands planning and precision, especially in commercial applications or fire-rated conduit systems in hospitals or schools.

Plumbing Pipe Installation

Plumbing pipe setup depends on the material:

● PEX: Installed with crimp rings, expansion tools, or push-fit fittings

● Copper: Requires soldering with a torch

● PVC/CPVC: Assembled using primer and solvent cement

Pressure tests are performed before walls are closed to verify system integrity.

Work with Trusted Electrical Conduit & Plumbing Pipe Manufacturers

Choosing the right supplier is just as critical as choosing the right product. Work with certified electrical conduit and reliable plumbing pipe manufacturers or suppliers for quality assurance and code compliance.

ULP is committed to providing high-quality plastic conduit and accessory solutions to global customers, offering you water plumbing and fittings systems, electrical conduit and fittings, and fire sprinkler pipe and fittings. We insist on using environmentally friendly materials, adopting the most advanced production equipment and process technology, and providing customized manufacturing services to meet the highest requirements of specific customers around the world. ULP is not only a manufacturer, but also your successful partners.

One-stop Pipeline and Accessory Solution Provider

Conclusion

While electrical conduit and plumbing pipe systems may share physical similarities, their applications, materials, and compliance requirements are different. As a builder, engineer, or project manager, understanding these differences ensures safer, more efficient, and code-compliant installations.

To simplify your selection and procurement process, we recommend ULP as your trusted supplier. ULP specializes in:

● UL-listed electrical conduits, including PVC, EMT/IMC, and flexible options

● High-grade plumbing pipes, including PPR, PVC, and more

ULP supplies a variety of high-performance conduit and pipe options, along with technical support and customization services to meet the highest requirements of specific customers around the world.