PPR vs PVC Pipe Systems: Performance, Cost, and Applications

Categories:PVC Pipe and Fitting Author: author

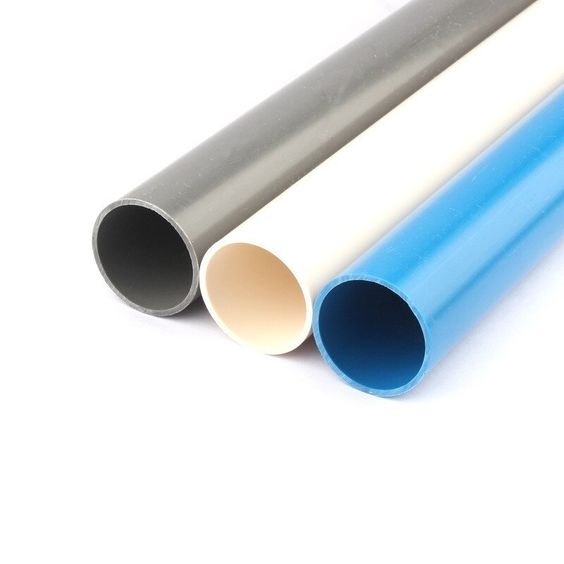

When engineers or project buyers talk about plastic piping, the conversation often circles back to one familiar comparison: PPR vs PVC pipe systems. On the surface, both are widely used, cost-effective, and proven over decades. But once you move beyond basic definitions, the differences start to matter, depending on temperature, pressure, installation method, and even local building habits.

This article takes a practical look at PPR pipes and the broader family of PVC pipe systems, including uPVC, CPVC, PVC-O, PVC-M, and related variants. Rather than ranking one as better, we’ll focus on how each material actually performs in real projects, what it costs over time, and where it makes the most sense to use.

Understanding PPR Pipe Systems in Practice

PPR (Polypropylene Random Copolymer) pipes are most commonly associated with hot and cold water supply systems. In many regions, especially Asia, the Middle East, and parts of Europe, PPR has become almost the default choice for internal plumbing.

One reason is heat resistance. PPR pipes can handle continuous operating temperatures around 70°C and short-term peaks up to 95°C. That makes them suitable for domestic hot water, central heating loops, and certain industrial fluid systems.

Another defining feature is heat fusion welding. PPR pipes and fittings are joined by melting both surfaces and fusing them together. When done correctly, the joint becomes as strong as the pipe itself, eliminating leak paths caused by adhesives or mechanical threads.

PPR Pipe for Cold and Hot Water

PVC Pipe Systems: More Than Just PVC

Unlike PPR, PVC pipe systems are not a single product category. They are a family of materials designed for very different conditions.

UPVC (Unplasticized PVC)

UPVC pipes are rigid, lightweight, and corrosion-resistant. They are widely used in cold water supply, drainage, sewage systems, cable protection, and agricultural irrigation. Because UPVC contains no plasticizers, it maintains structural stability over long periods.

UPVC performs well at ambient temperatures but is not suitable for hot water. Prolonged exposure to high temperatures can cause deformation or loss of strength.

CPVC (Chlorinated PVC)

CPVC pipes bridge the gap between UPVC and PPR. By increasing chlorine content, CPVC gains higher temperature resistance, allowing it to handle hot water systems up to around 90°C.

CPVC is often used in commercial buildings, hotels, hospitals, and industrial plants where hot water is needed but heat fusion systems are not preferred. Solvent cement joints are quicker to install than PPR fusion, especially for retrofitting projects.

PVC-O, PVC-M and PVC-UH

PVC-O (Oriented PVC) is engineered for pressure applications such as municipal water transmission. Molecular orientation improves strength while reducing wall thickness, which lowers material usage and transportation cost.

PVC-M (Modified PVC) offers improved impact resistance and toughness, making it suitable for demanding environments where mechanical stress is a concern.

PVC-UH (Ultra High Impact PVC) is developed to provide enhanced impact resistance compared with standard uPVC. It maintains the chemical stability and

Together, these variants make PVC pipe systems extremely versatile — from underground infrastructure to indoor plumbing.

Performance Comparison: Where the Differences Show Up?

In daily use, performance differences between PPR and PVC pipe systems usually appear in three areas: temperature, pressure behavior, and long-term stability.

PPR handles thermal cycling better. Repeated heating and cooling has less impact on welded joints compared to solvent-cement PVC connections. This is why PPR dominates residential hot water systems.

PVC systems, especially UPVC and PVC-O, excel in pressure stability for cold water and large-diameter pipelines. They have lower thermal expansion rates than PPR, which simplifies pipe support design in long runs.

Chemical resistance is another factor. Both materials resist corrosion, but specific industrial fluids may favor one over the other depending on concentration and temperature.

Cost Is Not Just Material Price

Many buyers compare PPR and PVC by looking only at pipe price per meter. In reality, total system cost tells a different story.

PPR pipes usually cost more upfront. Fusion tools add to initial investment, and installation speed depends heavily on worker experience. However, long service life and low failure rates can offset these costs in residential and commercial buildings.

PVC pipe systems, particularly UPVC, are generally more economical at scale. Lower material cost, faster installation, and broad fitting availability make PVC attractive for large infrastructure, irrigation, and industrial projects.

Maintenance also differs. PVC joints are easier to repair or modify, while PPR systems often require cutting and re-fusion.

Quick Comparison: PPR vs PVC Pipe Systems

|

Aspect |

PPR Pipe Systems |

PVC Pipe Systems |

|

Typical Applications |

Hot & cold water supply, indoor plumbing, heating loops |

Cold water supply, drainage, irrigation, |

|

Temperature Resistance |

Continuous use around 70°C, short-term up to 95°C |

UPVC: cold water only; CPVC: up to ~90°C; |

|

Jointing Method |

Heat fusion welding, joint strength equals pipe body |

Solvent cement, rubber ring, or mechanical joints |

|

Installation Speed |

Slower, depends on fusion tools and skilled labor |

Generally faster, especially for large-scale projects |

|

Pressure Performance |

Stable for building systems, less common in large diameters |

Strong in pressure pipelines, especially PVC-O and uPVC |

|

Thermal Expansion |

Relatively high, requires proper pipe support design |

Lower than PPR, easier to control in long straight runs |

|

Maintenance & Modification |

Cutting and re-fusion required |

Easier to repair or modify on site |

|

Material Cost |

Medium to high |

Wide range; uPVC usually more economical |

|

Typical Service Life |

50 years or more under correct conditions |

50+ years depending on material type and application |

Real-World Applications: Choosing What Actually Works

In real projects, material choice is rarely theoretical.

● For residential plumbing, PPR is often chosen for hot and cold water inside buildings, while uPVC handles drainage and vent systems.

● In commercial and industrial buildings, CPVC may replace PPR when installation speed, fire performance, or code compliance is critical.

● For municipal water supply and irrigation, PVC-O and uPVC dominate due to pressure efficiency, durability, and cost control.

● In industrial fluid transport, both systems appear — selection depends on temperature, chemical exposure, and maintenance philosophy.

Beyond Material Choice: Manufacturing Quality in Plastic Pipe Systems

Regardless of material, pipe performance depends heavily on manufacturing consistency. Dimensional accuracy, raw material quality, and quality control all influence how a system behaves over decades.

As a global plastic pipe manufacturer, ULP focuses on providing stable, application-specific solutions rather than one-size-fits-all products. With over 15 years of experience and an automated production workshop covering more than 10,000 square meters, ULP supplies PPR pipes, UPVC, CPVC, HDPE, PVC-O, PVC-M, and a full range of fittings for industrial, commercial, and residential use.

ULP also supports OEM/ODM services, including logo printing, color customization, size adjustment, and packaging options, allowing distributors and project owners to build consistent, market-ready pipe systems.

One-stop Plastic Pipe and Fittings Solution

Conclusion: PPR vs PVC Is About Application, Not Preference

There is no universal winner in the PPR vs PVC pipe systems discussion. Each material exists because it solves specific problems well.

PPR shines in hot water and indoor plumbing where joint integrity and thermal performance matter most. PVC systems, from UPVC to CPVC and PVC-O, offer unmatched flexibility across infrastructure, industrial, and commercial applications.

Choosing the right system means understanding real operating conditions, local installation practices, and long-term maintenance needs. Working with an experienced supplier like ULP, who offers a one-stop plastic pipe and fittings solution, helps ensure that material choice translates into reliable performance on site. Browse our wide range of pipe and fitting collection or contact us to know more.