EMT vs. Rigid Conduit for Wiring: How to Choose the Right Type?

Categories:PVC Pipe and Fitting Author: author

When it comes to electrical wiring systems, conduit selection is rarely a one-size-fits-all decision. On paper, EMT conduit and rigid conduit both serve the same basic purpose: protecting electrical wires and ensuring safe power distribution. But in real projects—whether commercial buildings, industrial plants, infrastructure, or OEM manufacturing—the difference between EMT and rigid conduit often shows up in installation speed, long-term durability, compliance requirements, and overall project cost.

This guide does not argue which conduit is better. Instead, it focuses on how to choose the right conduit based on use case, environment, and practical project needs.

What EMT and Rigid Conduit Actually Are?

EMT (Electrical Metallic Tubing)

EMT is a thin-wall steel conduit (often galvanized). It's widely used in commercial wiring, light industrial work, and many indoor runs where you want a clean, professional pathway and decent physical protection without the weight and labor of heavy rigid.

Common EMT use cases

● Indoor exposed runs in warehouses, shops, and retail spaces

● Electrical rooms and utility corridors

● Drop-downs to equipment in relatively controlled environments

● Projects where speed and flexibility matter

Rigid Conduit

When people say rigid conduit, they may mean:

● Rigid Metal Conduit (RMC) or IMC: Thick-wall steel (or aluminum), threaded, heavy-duty.

● Rigid PVC Conduit: Plastic, non-metallic, corrosion resistant, solvent-welded, used a lot underground or in wet/corrosive areas.

So rigid is more like a category: maximum stiffness and stronger protection, but higher installation effort compared to EMT.

Common rigid conduit use cases

● Outdoor service entrances and exposed exterior runs

● Mechanical rooms with higher impact risk

● Areas with corrosion exposure (often rigid PVC conduit)

● Underground conduit runs (often rigid PVC conduit)

● Industrial sites where equipment movement is common

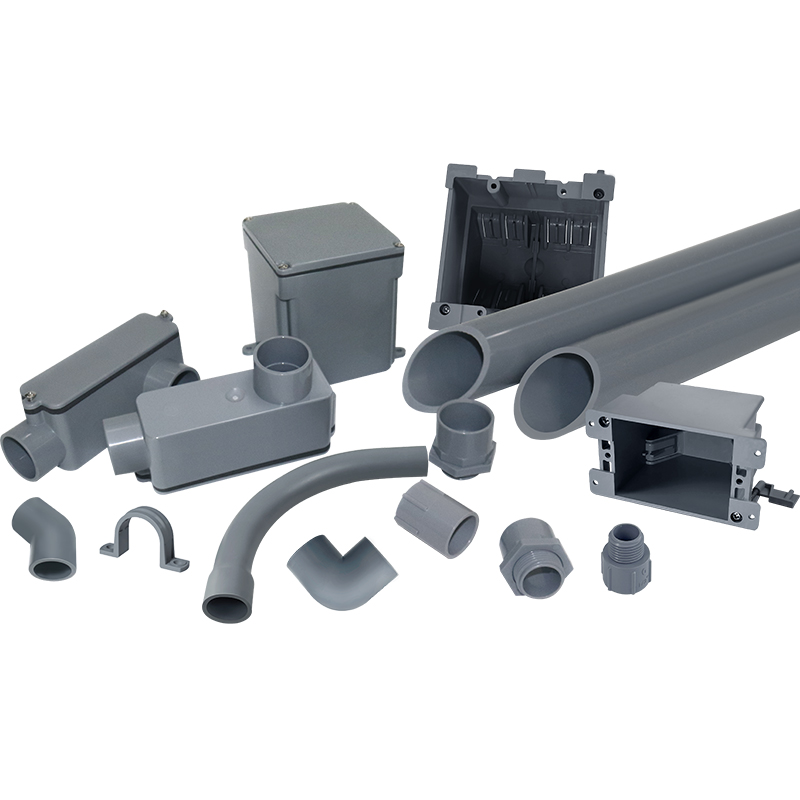

UPVC Electrical Conduit and Fitting

Side-by-Side Comparison

1. Strength and impact resistance

Rigid Metal Conduit (RMC) is typically the toughest. If the conduit could be struck by carts, pallets, or tools, rigid metal buys you safety margin.

EMT is strong enough for many indoor jobs, but it can dent if it gets hit hard.

Rigid PVC Conduit doesn't dent like metal, but it can crack if abused or installed in extreme cold without proper handling.

Rule of thumb: If damage risk is high, rigid tends to be safer. If it's a standard indoor run, EMT is often perfectly fine.

2. Corrosion and wet locations

EMT (galvanized) can do well indoors, but in harsh outdoor coastal air, chemical exposure, or constantly wet areas, corrosion becomes a serious concern. You can mitigate it with proper fittings and coatings, but it's still a consideration.

Rigid Metal Conduit has better durability than EMT, but corrosion can still occur if the environment is aggressive.

Rigid PVC Conduit is the “easy answer” for corrosion resistance in many cases. It's commonly selected for underground conduit, wastewater facilities, agriculture, and areas where metal would degrade.

If you're doing a parking lot lighting feed or a trench run to an outbuilding, rigid PVC conduit often becomes the practical choice.

3. Installation speed and labor

Labor can cost more than materials, and conduit choice affects labor a lot.

EMT is generally faster: it bends easily with standard benders, and it's lighter to carry and mount. EMT fittings (set-screw or compression) are familiar to most electricians.

Rigid Metal Conduit is heavier and usually needs threading or threaded fittings. Bending rigid also takes more effort and equipment.

Rigid PVC Conduit is light and cuts easily, but it requires correct solvent cement technique, cure time awareness, and good planning for expansion and support spacing.

In short: if you want speed on an indoor commercial build-out, EMT often keeps the schedule moving. If you're outside, underground, or in corrosive conditions, rigid choices may save trouble later.

4. Cost (material and installed cost)

Prices change by region and market, but patterns stay similar:

EMT often has a good balance of price and performance, especially indoors.

Rigid Metal Conduit costs more and can raise labor time, but it can reduce repairs and risk in high-abuse areas.

Rigid PVC Conduit material cost can be competitive, and labor can be efficient in trenches—yet fittings, transitions, and supports can add up.

5. Grounding and electrical performance

EMT and Rigid Metal Conduit can serve as an equipment grounding path when installed correctly (depending on local code and application). You still need to do it right: correct couplings, proper tightening, continuity, and approved fittings.

Rigid PVC Conduit is non-metallic; it does not provide a grounding path by itself, so a grounding conductor is typically required.

6. Bending, routing, and jobsite flexibility

EMT shines when you need lots of offsets, kicks, and small changes—especially in renovation work where obstacles show up late.

Rigid Metal Conduit is less forgiving; it rewards accurate planning.

Rigid PVC Conduit is straight and clean in long runs, but it needs thoughtful expansion handling outdoors and careful alignment for solvent welds.

If your project has a lot of last-minute routing changes, EMT usually feels less stressful.

Typical Scenarios: Choosing What's Most Suitable

1. Indoor commercial space (exposed conduit)

If the space is dry and protected, EMT is commonly chosen for neat appearance, efficient installation, and broad availability of EMT conduit fittings like couplings, connectors, straps, and elbows.

2. Outdoor wall run with risk of impact

Rigid conduit provides higher impact protection and is more robust long-term. If conduit is exposed outdoors and could be hit, Rigid Metal Conduit may be preferred due to strength and durability. In coastal or corrosive air, you may also consider rigid PVC conduit with proper transitions, depending on local code and engineering preference.

3. Underground conduit to a detached building

This is a classic rigid PVC conduit job: corrosion resistance, smooth pulling, and trench-friendly installation. Using quality PVC conduit fittings (couplings, sweeps, adapters) matters a lot here, because a poor-fitting joint can create pull headaches.

4. Light industrial with occasional mechanical exposure

Sometimes the right answer is mixed: EMT in low-risk areas, rigid where forklifts or pallet jacks are near, and rigid PVC where chemicals or washdowns exist. That hybrid approach is common and often the most cost-smart.

Fittings and Accessories: The Part People Underestimate

Many conduit problems are not caused by the pipe itself. They come from:

● loose or mismatched connectors

● poor threads or inconsistent dimensions

● cracking or leaking joints (for PVC)

● missing support spacing or incorrect straps

● transitions done with the wrong adapter

So when comparing EMT vs. rigid conduit, it's also a comparison of the whole system: conduit, conduit fittings and installation method.

If you're sourcing for a project, look for a supplier that can provide a complete set: plastic pipe and fittings, connectors, couplings, elbows/sweeps, adapters, and packaging that protects threads and ends during shipping.

What to Consider Before You Decide?

1. Where is it installed? Indoor, outdoor, underground conduit, wet location, corrosive area?

2. What's the damage risk? High-traffic, equipment movement, impact potential?

3. Who's installing it? Crew skill set can affect schedule and error rates.

4. How tight is the schedule? EMT often accelerates indoor jobs.

5. How important is long-term maintenance? Rigid choices can reduce repairs in harsh sites.

6. What does your local code require? Always verify with local rules and inspectors.

7. Do you need custom branding or special packaging? This matters for distributors and importers.

How ULP Supports Conduit System Projects?

Choosing the right conduit type is one part; reliably sourcing it is another. ULP positions itself as a one-stop pipeline system solutions provider, with more than 15 years of manufacturing experience in pipes and fittings, and a focus on stable quality and customer service.

For buyers who want a smoother procurement process, ULP offers:

● one-stop plastic pipe and fittings solution (helpful when you want a consistent system rather than mixing suppliers)

● OEM/ODM service with custom logo, color, and size options

● multiple packaging options to match your warehouse, retail, or distributor needs

● an automated production workshop and a factory area of over 10,000 square meters, with 100+ employees

● a dedicated technical and QC team to support product consistency

If your project involves rigid PVC conduit and matching PVC conduit fittings, or you're building a private-label lineup for your market, ULP customization and manufacturing scale can be practical—especially when you want competitive pricing without gambling on quality.

Conclusion: Choosing the Right Conduit with ULP

There is no universal best conduit. EMT conduit excels in speed, flexibility, and cost efficiency for indoor applications. Rigid conduit stands out in strength, durability, and environmental resistance. The right choice depends on application, environment, budget, and installation conditions.

For projects that need a dependable supply of conduit and fittings, OEM/ODM customization, and a one-stop plastic pipe and fittings solution, ULP can support your conduit system decisions with manufacturing experience, quality control, and flexible packaging options.