PVC vs HDPE Pipes: What’s the Difference & Which Is Better for Your Project?

Categories:PVC Pipe and Fitting Author: author

When selecting piping systems for construction, water management, industrial operations, or agricultural applications, two materials often rise to the top: PVC (Polyvinyl Chloride) and HDPE (High-Density Polyethylene). Both types of plastic pipes offer performance, cost-effectiveness, and adaptability across multiple industries, but they have significant differences in physical characteristics, installation requirements, and application suitability.

This article provides a comparison of PVC vs HDPE pipes, highlights their typical uses, and offers guidance on how to determine which type may better suit your project's needs.

Introduction to PVC and HDPE Pipes

What is PVC Pipe?

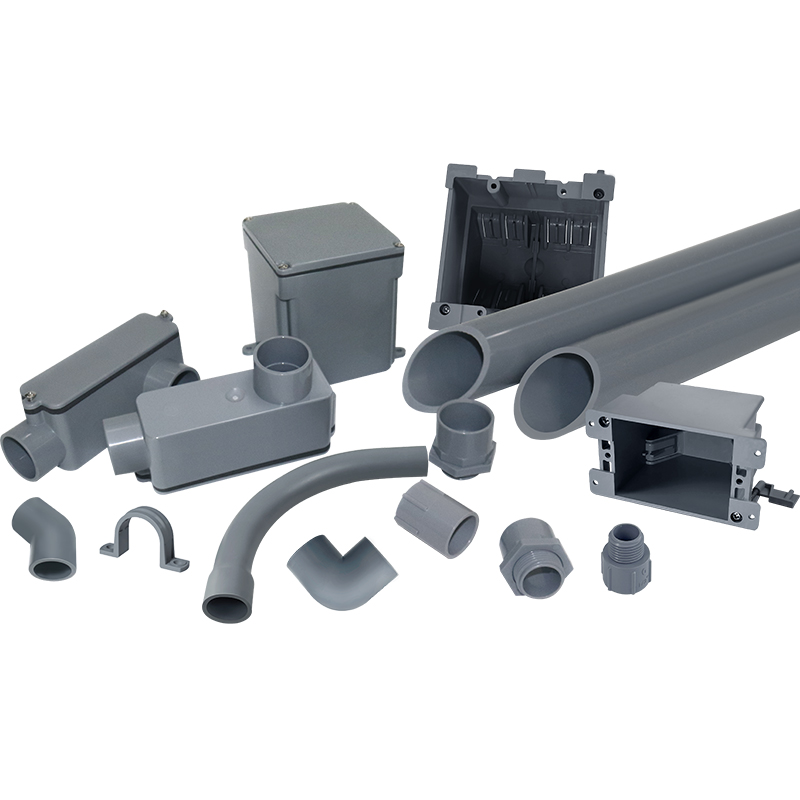

PVC pipe is made from polyvinyl chloride, a rigid plastic that has been widely used in plumbing and drainage systems for decades. Known for its chemical resistance, ease of installation, and affordability, PVC is commonly used in residential, commercial, and light industrial projects. It is most often seen in white or gray and joins together with solvent-based adhesives.

UPVC SCH40/SCH80 Pipes & Fittings

What is HDPE Pipe?

HDPE pipe, or high-density polyethylene pipe, is a flexible, thermoplastic piping system known for its strength, resilience, and leak-proof jointing through heat fusion. HDPE tubes are frequently used for underground utilities, HDPE water plumbing systems, gas distribution, and HDPE irrigation pipes in agriculture due to their resistance to corrosion and stress cracking.

Comparing PVC and HDPE Pipes

When evaluating PVC versus HDPE, it's essential to understand how they differ in terms of performance, installation, and long-term use.

Flexibility and Strength

● PVC is rigid and can break under pressure or shifting soils, especially in cold climates.

● HDPE is highly flexible and can bend without breaking. It makes the HDPE flexible pipe ideal for underground or dynamic environments.

Jointing and Leak Prevention

● PVC pipes are joined using solvent cement, which is quick but can degrade over time if not properly applied.

● HDPE pipes and fittings are fused using heat (butt fusion or electrofusion), resulting in strong, seamless joints that reduce the risk of leaks.

Pressure Resistance

● HDPE black pipe can handle high-pressure fluids and water hammer better than PVC due to its flexibility and tensile strength.

● PVC is effective in steady-pressure environments but may fail under sudden pressure surges.

Chemical and Corrosion Resistance

● Both materials are resistant to many chemicals, but HDPE fittings generally offer broader chemical compatibility.

● HDPE pipes are particularly advantageous in corrosive environments, such as industrial waste or chemical transfer lines.

Lifespan and Durability

● PVC has a typical lifespan of 50–70 years when used appropriately.

● HDPE can exceed 100 years in many applications, especially when used underground or in HDPE water plumbing systems.

Quick Comparison Table: PVC vs HDPE Pipes

| Feature | PVC Pipe | HDPE Pipe |

| Material Composition | Polyvinyl Chloride (rigid plastic) | High-Density Polyethylene (flexible plastic) |

| Flexibility | Rigid; limited flexibility | Flexible; allows some degree of bending |

| Jointing Method | Solvent cement bonding | Heat fusion (e.g., butt fusion, electrofusion) |

| Pressure Handling | Suitable for steady or moderate pressure | Suitable for varying and higher pressure |

| Chemical Resistance | Resistant to many household and industrial chemicals | Compatible with a wide range of chemical substances |

| Corrosion Resistance | Resistant to most forms of corrosion | Resistant to chemical, soil, and moisture corrosion |

| UV Stability | May require coating or protection from UV exposure | Often UV stabilized (especially black HDPE) |

| Common Applications | Plumbing, drainage, and electrical conduit | Water systems, gas transport, irrigation, and utilities |

| Typical Lifespan | Estimated 50–70 years, depending on conditions | Estimated 50–100+ years based on use and environment |

| Installation Tools | Standard hand tools; adhesive required | Fusion welding equipment is often required |

| Initial Cost | Generally lower material and installation costs | Higher initial investment, depending on system scale |

Common Applications of PVC and HDPE Pipes

Both PVC and HDPE are used in overlapping industries, but their properties make them more suitable for different types of applications.

Common Uses for PVC Pipe

● Residential Plumbing: Drain-waste-vent (DWV) systems and cold-water delivery.

● Irrigation Systems: Sprinkler and surface irrigation setups.

● Construction Drainage: Rainwater downspouts and stormwater management.

● Electrical Conduit: In some cases, rigid PVC is used for cable protection.

Common Uses for HDPE Pipe

● Underground Utilities: HDPE conduit for electrical and telecommunications cabling.

● Municipal Water Systems: Pressurized mains, sewer force mains, and HDPE pipe fittings for municipal infrastructure.

● Agriculture: Drip and subsurface irrigation using HDPE irrigation pipe.

● Industrial Processing: Transporting chemicals, slurry, or compressed gases.

Each material’s suitability depends on factors like soil conditions, load stress, fluid type, and environmental exposure.

How to Choose Based on Your Project Needs?

Choosing between PVC and HDPE pipes is not about which one is better overall, but which is better for your specific application. Consider the following criteria:

Environmental Conditions

● In areas with shifting soil, earthquakes, or freezing temperatures, HDPE flexible pipe offers better resilience.

● For above-ground or indoor installations where the environment is stable, PVC pipe may be sufficient and more cost-effective.

Pressure Requirements

● For low-pressure systems, PVC can be a budget-friendly solution.

● For high-pressure or variable-pressure scenarios (e.g., pump-driven irrigation or industrial systems), HDPE black pipe performs more reliably.

Installation Complexity

● PVC is easier to cut and join without specialized equipment, suitable for small-scale or DIY projects.

● HDPE, while requiring fusion equipment and training, offers long-term savings through fewer maintenance needs and higher reliability.

Budget and Lifecycle Costs

● PVC may have a lower initial material and labor cost.

● HDPE might cost more upfront, but typically offers lower total cost of ownership due to reduced leaks, repairs, and longer service life.

Frequently Asked Questions about PVC and HDPE Pipes

Can HDPE pipes be used for drinking water?

Yes, HDPE is approved for potable water applications and is widely used in HDPE water plumbing systems globally due to its non-toxic, corrosion-resistant properties.

Are PVC pipes safe for hot water applications?

Standard PVC pipes are not recommended for hot water. For hot water, CPVC (Chlorinated PVC) or HDPE may be better suited, depending on the system's temperature requirements.

Which pipe is more suitable for underground installations?

HDPE pipes, especially HDPE conduit and HDPE irrigation pipe, are better suited due to their flexibility and resistance to ground movement.

What type of jointing system is more reliable long term?

HDPE pipe fittings using heat fusion provide leak-free, monolithic joints, which are generally more durable than solvent-welded PVC joints.

Can I use PVC and HDPE pipes in the same system?

Generally, mixing the two is not ideal due to differences in jointing techniques and thermal expansion. If necessary, use appropriate transition fittings designed to connect PVC to HDPE.

What types of fittings are available for PVC and HDPE pipes?

● PVC fittings include tees, elbows, couplings, reducers, and valves, typically joined with solvent cement.

● HDPE pipe fittings include electrofusion fittings, butt fusion fittings, mechanical couplings, and transition fittings to connect with other materials (e.g., metal or PVC). For HDPE pipes and fittings, proper fusion technique is key to system integrity.

ULP Product Recommendation: One Source for Both PVC & HDPE Systems

At ULP, we provide a complete range of both PVC and HDPE piping products, including:

● HDPE conduit and fitting, such as HDPE drinking water pipe, HDPE irrigation pipe

● PVC conduit and fitting for water supply/drainage, and electrical conduit and fittings

Whether your project requires a flexible, long-lasting HDPE solution or a budget-friendly PVC system, ULP has the technical support and inventory to match your application. Contact us to get expert advice and product specifications tailored to your needs.

Conclusion

PVC and HDPE pipes both offer excellent solutions for different piping requirements. While PVC is more rigid and budget-friendly, HDPE provides superior durability, flexibility, and chemical resistance. By understanding each material’s advantages, installation methods, and use cases, you can confidently choose the right system for your project.

Always consider environmental conditions, pressure requirements, installation capacity, and lifespan goals when deciding. For large-scale infrastructure, dynamic environments, or high-pressure systems, HDPE is often preferred. For indoor, low-pressure, or cost-sensitive installations, PVC remains a solid option.

Need help choosing the right solution? Contact ULP for guidance on our full range of PVC and HDPE pipes and accessories.