SCH 40 vs. SCH 80 PVC Conduit and Fittings: Differences and How to Choose

Categories:PVC Pipe and Fitting Author: author

When it comes to electrical installations and plumbing infrastructure, selecting the right type of PVC conduit and fittings can significantly influence the durability, safety, and cost-effectiveness of your project. Two of the most commonly used types of polyvinyl chloride conduit are Schedule 40 (SCH 40) and Schedule 80 (SCH 80). Although they may look similar externally, their physical properties, applications, and regulatory implications differ greatly.

In this comprehensive guide, we’ll explore the key differences between SCH 40 vs. SCH 80 PVC conduit and fittings, help you determine the best option based on your project needs, and examine their typical applications in residential, commercial, and industrial environments.

What Is PVC Conduit?

PVC conduit (polyvinyl chloride conduit) is a non-metallic pipe used to house and protect electrical wires and cables. Known for its durability, corrosion resistance, and non-conductive nature, it’s a popular choice for both above-ground and underground electrical systems.

PVC conduit systems consist of two primary components:

● PVC Conduit Pipes

● PVC Conduit Fittings (elbows, couplings, junction boxes, reducers, etc.)

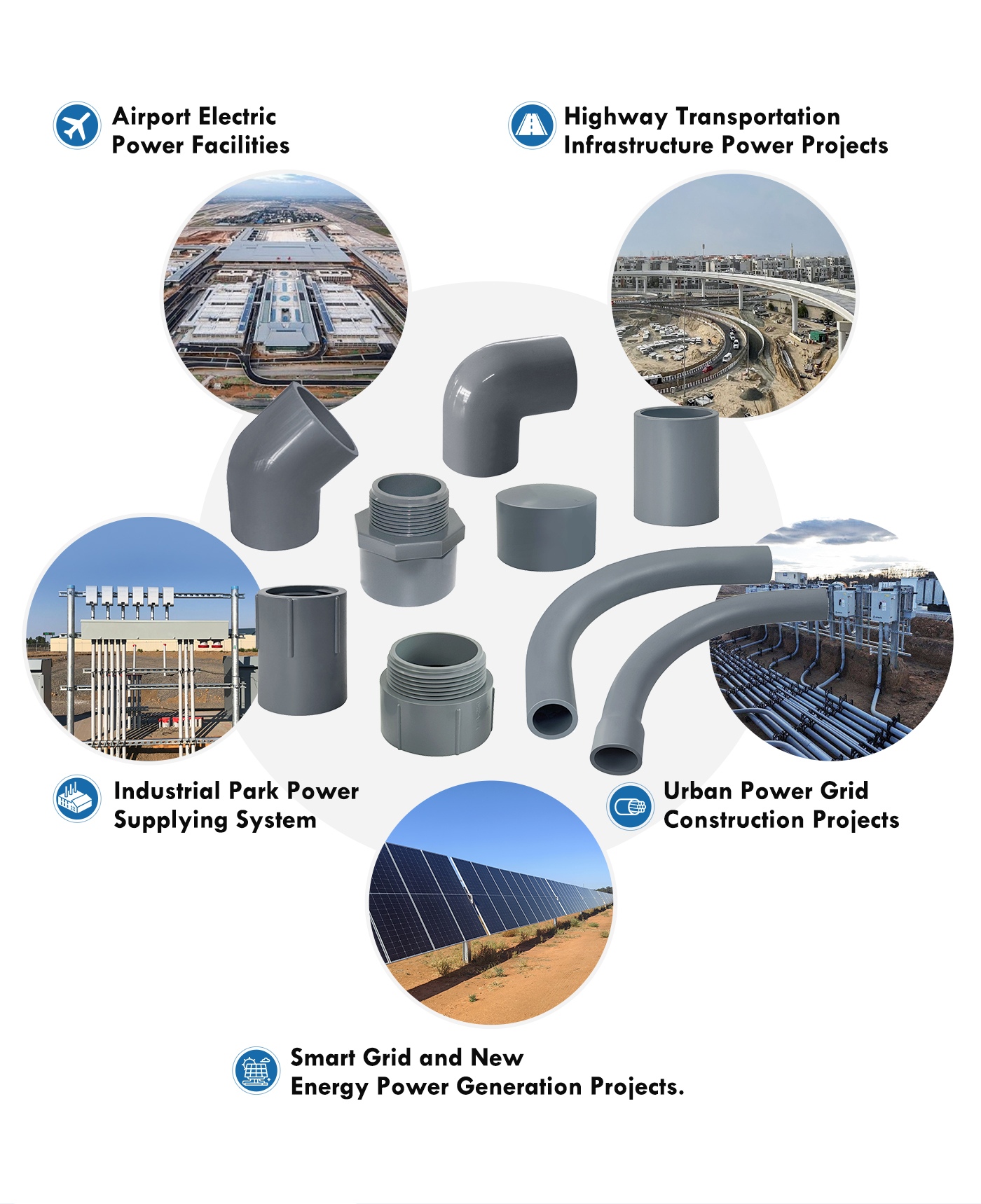

These systems are often used in:

● Electrical wiring systems

● Telecommunications

● Data centers

● Commercial and residential infrastructure

● Water and irrigation pipelines

Understanding "Schedule" in PVC Piping

In PVC terminology, "Schedule" refers to the wall thickness of the pipe, which impacts its pressure rating and structural integrity.

Schedule 40 (SCH 40): Features a thinner wall, offering a larger inner diameter and lighter weight.

Schedule 80 (SCH 80): Has a thicker wall, providing greater strength and higher pressure resistance.

SCH 40 PVC Conduit and Fittings: Overview

Schedule 40 PVC conduit is widely used in residential electrical projects and low-pressure systems. Its lighter weight and ease of installation make it a favorite among electricians and DIY enthusiasts.

Key Features:

● White or light gray color

● Thin wall thickness

● Lightweight and flexible

● Cost-effective

● Suitable for direct burial when rated as PVC Type EB (Encased Burial)

Common Applications:

● Residential wire routing

● Non-metallic underground duct systems

● Indoor conduit systems

● Irrigation and sprinkler systems

Schedule 40 PVC electrical conduit is often preferred for projects where physical protection is necessary but heavy external pressure or high temperatures are not anticipated.

SCH 80 PVC Conduit and Fittings: Overview

Schedule 80 PVC conduit is engineered for high-pressure and high-stress environments. Its thicker wall and darker gray color distinguish it from SCH 40. It is especially valuable in industrial environments where safety, chemical resistance, and structural integrity are top priorities.

Key Features:

● Dark gray in color

● Thicker wall for enhanced strength

● Suitable for above-ground and underground installation

● Higher temperature and impact resistance

● Complies with NEMA TC-2 and UL 651 standards

Common Applications:

● Industrial electrical conduit systems

● Underground conduit beneath roadways or driveways

● Wastewater treatment facilities

● Chemical processing plants

● Agricultural and livestock environments

Some Schedule 80 conduit manufacturers also offer UV-stabilized and fire-resistant PVC conduit for outdoor and hazardous applications.

Key Differences Between SCH 40 and SCH 80 PVC Conduit and Fittings

|

Feature |

SCH 40 PVC |

SCH 80 PVC |

|

Wall Thickness |

Thinner |

Thicker |

|

Internal Diameter |

Larger |

Smaller |

|

Color |

White or light gray |

Dark gray |

|

Pressure Rating |

~120 PSI (varies by size) |

~210 PSI (varies by size) |

|

Impact Resistance |

Moderate |

High |

|

Flexibility |

More flexible |

More rigid |

|

Installation Difficulty |

Easier to cut and install |

Requires more effort and tools |

|

Typical Applications |

Residential and light commercial |

Industrial and heavy-duty environments |

|

Price Point |

More affordable |

More expensive |

Common Misconceptions

Color Is Not Always Definitive: While color is a helpful guide, always check the printed schedule on the pipe.

Mixing Schedules: Fittings are available for both schedules, but do not mix SCH 40 and SCH 80 in the same pressure line unless approved by code and manufacturer.

Pressure Ratings Decline with Pipe Size: Larger pipes, even in the same schedule, have lower pressure ratings due to increased diameter.

Typical Products and Sizing

Both schedule 40 PVC fittings and schedule 80 PVC fittings come in a wide range of sizes and types: elbows, tees, couplings, unions, ball valves, and more. Schedule 40 conduit fittings are widely used for standard residential and commercial installations, while schedule 80 conduit fittings are chosen for demanding, high-stress environments.

Installation and Compatibility

Outer Diameter (OD): The OD is the same for both schedules of the same nominal size, allowing for interchangeability in some fittings.

Inner Diameter (ID): SCH 80 pipes have a smaller ID due to thicker walls, which may slightly restrict flow.

Joining Methods: Both schedules use the same solvent welding or threaded joining techniques.

How to Choose Between SCH 40 and SCH 80 PVC Conduit?

Choosing the right PVC conduit type isn’t just about size—it’s about performance, safety, and long-term reliability. Here’s a simplified guide to help you make the best choice:

1. Where Will It Be Installed?

Indoor, dry, low-impact areas

● Use SCH 40 PVC conduit (e.g., residential walls, basements, garages)

● It’s lightweight, easy to work with, and cost-effective.

Outdoor, high-traffic, or harsh environments

● Go for SCH 80 PVC conduit

● Ideal for exposure to sunlight, chemicals, or mechanical stress.

2. What Kind of Load or Pressure Will It Handle?

Light-duty use

● SCH 40 PVC electrical conduit handles most general wiring and low-pressure systems.

Heavy-duty or high-pressure systems

● Choose Schedule 80 conduit for applications like underground conduit beneath driveways, industrial areas, or machinery zones.

3. Do Local Codes Apply?

Always check NEC (National Electrical Code) and local building codes.

Some applications may require UL-listed SCH 80 conduit, especially:

● For service entrance conductors

● In hazardous or corrosive environments

● For commercial and industrial conduit systems

4. What’s Your Budget?

SCH 40: More affordable, ideal for budget-conscious residential or small commercial projects.

SCH 80: Higher upfront cost, but greater durability and long-term savings in demanding environments.

5. Are the Fittings Compatible?

Match conduit with the same schedule-rated PVC fittings.

Don’t mix SCH 40 and SCH 80 conduit fittings—even if they share outer diameter, their inner dimensions and pressure ratings differ.

Installation Tips for PVC Conduit Systems

Regardless of the schedule, follow best practices to ensure safety and system longevity:

● Use the right solvent cement and primer for bonding.

● Avoid mixing SCH 40 and SCH 80 in pressure-sensitive systems.

● Allow for expansion and contraction due to temperature changes.

● Use expansion couplings for long runs in exposed areas.

● Label the conduit appropriately, especially in multi-use installations.

Also, some PVC electrical conduit manufacturers offer pre-lubricated conduit or inner coatings to reduce wire-pulling friction—ideal for long or complex cable runs.

Where to Buy: Top PVC Conduit Manufacturers and Suppliers

For bulk orders or commercial installations, consider partnering with a reliable manufacturer and supplier that provides project-specific technical support and custom conduit and fitting solutions.

ULP is committed to providing high-quality plastic conduit and fitting solutions to global customers, meeting the needs of their respective markets, and becoming a trusted global partner for enterprises. Our main businesses are water plumbing and fittings systems, electrical conduits and fittings, fire sprinkler pipes and fittings, and other professional solutions.

High-quality Plastic Conduit and Fitting Solutions Provider

Conclusion

Understanding the differences between SCH 40 vs. SCH 80 PVC conduit and fittings is essential for successful project planning and execution. While Schedule 40 offers a cost-effective solution for general-purpose applications, Schedule 80 delivers enhanced strength and reliability for high-demand environments.

Whether you're building a residential electrical system or managing a high-pressure industrial setup, choosing the correct PVC conduit schedule ensures performance, safety, and code compliance. Partnering with a reputable PVC conduit supplier or industrial PVC pipe manufacturer will help you source quality materials tailored to your specific application. ULP provides high-quality plastic conduit and fitting solutions to global customers. Feel free to contact us for more details.