Top 5 Electrical Conduit Types: UPVC, CPVC, HDPE, EMT & IMC

Categories:PVC Pipe and Fitting Author: author

When it comes to electrical installations, safety, durability, and efficiency all depend on the choice of conduit. Electrical conduits are not just protective channels for wires; they are the backbone of reliable power distribution in residential, commercial, and industrial projects. Among the most widely used options are UPVC, CPVC, HDPE, EMT, and IMC conduits.

We will explore these five conduit types, compare them, and introduce common accessories while explaining why choosing a trusted manufacturer like ULP—a global provider of pipeline system solutions with over 15 years of experience—can ensure the success of your projects.

1. UPVC Electrical Conduit

UPVC (Unplasticized Polyvinyl Chloride) conduit has become a staple in electrical installations globally. Its rigidity and durability make it ideal for protecting cables in buildings.

Key Advantages:

● Corrosion Resistance: Unaffected by moisture, chemicals, or salty environments.

● Lightweight and Easy to Install: Simple cutting, bending, and joining.

● Cost-Effective: Ideal for residential projects.

● Non-Conductive: Adds safety against accidental shocks.

Applications:

● Residential housing wiring

● Low- to medium-voltage electrical systems

● Commercial interiors with limited moisture exposure

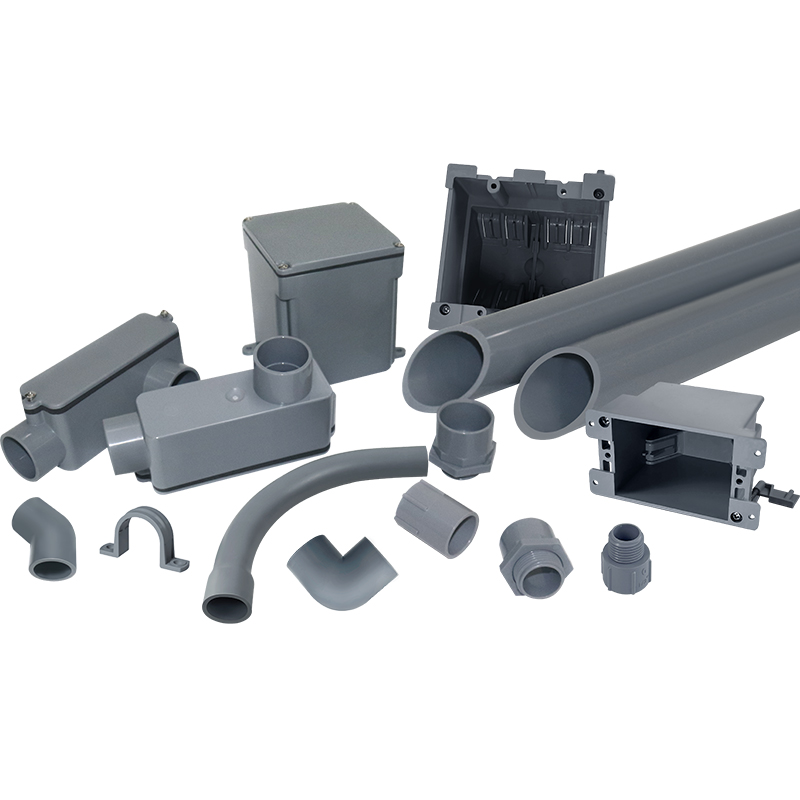

PVC-U Electrical Conduit and Fitting

2. CPVC Electrical Conduit

CPVC (Chlorinated Polyvinyl Chloride) conduits offer superior temperature resistance, making them suitable for demanding environments.

Key Advantages:

● Heat Resistance: Handles higher temperatures better than UPVC.

● Chemical Stability: Suitable for industrial environments.

● Durability: Longer lifespan in demanding conditions.

Applications:

● Industrial plants

● Commercial kitchens and factories

● High-temperature areas

3. HDPE Electrical Conduit

HDPE (High-Density Polyethylene) conduits combine flexibility and strength, especially for underground and outdoor use.

Key Advantages:

● Flexibility: Ideal for long underground runs with fewer joints.

● Impact Resistance: Durable under heavy load or rough environments.

● Moisture and UV Resistance: Suitable for outdoor applications.

● Longevity: Resistant to cracking and environmental stress.

Applications:

● Underground electrical wiring

● Telecom and fiber optic cable protection

● Outdoor industrial installations

4. EMT Conduit

EMT (Electrical Metallic Tubing) is a lightweight steel conduit used widely in commercial buildings.

Key Advantages:

● Strength: Protects cables against mechanical damage.

● Versatility: Suitable for both exposed and concealed wiring indoors.

● Fire Safety: Steel doesn't burn, adding safety.

Applications:

● Commercial offices

● Hospitals and schools

● Areas requiring exposed conduit with aesthetic appeal

5. IMC Conduit

IMC (Intermediate Metal Conduit) offers a balance of strength and manageability, being stronger than EMT but easier to handle than RMC.

Key Advantages:

● Enhanced Protection: Thick-walled steel resists heavy mechanical stress.

● Corrosion Resistance: Galvanized coating protects against rust.

● Versatility: Suitable for indoor and outdoor use.

Applications:

● Industrial facilities

● Outdoor installations in high-stress environments

Quick Comparison of Electrical Conduit Types

|

Conduit Type |

Material |

Strength |

Heat Resistance |

Corrosion Resistance |

Flexibility |

Applications |

|

UPVC |

Rigid plastic |

Medium |

Low–Medium |

Excellent |

Low |

Residential wiring, commercial interiors |

|

CPVC |

Chlorinated PVC |

Medium–High |

High |

Excellent |

Low |

Industrial plants, hot environments |

|

HDPE |

High-density polyethylene |

Medium |

Medium |

Excellent |

High |

Underground, outdoor, telecom/fiber |

|

EMT |

Thin-walled steel tubing |

High |

High |

Good (indoor) |

Medium |

Commercial interiors, exposed wiring |

|

IMC |

Galvanized steel |

Very High |

High |

Very Good (indoor & outdoor) |

Medium–Low |

Industrial plants, outdoor high-stress areas |

Key Takeaways

UPVC: Best for budget-friendly, general-purpose wiring.

CPVC: Better for high-temperature or chemical environments.

HDPE: Flexible and durable, excellent for underground or outdoor work.

EMT: A cost-effective option for commercial buildings.

IMC: Stronger than EMT, suitable for heavy-duty industrial or outdoor installations.

Common Fittings for Electrical Conduit Systems

Electrical conduit systems are more than just pipes — accessories are essential for safe installation, connection, and maintenance. Here are the most common fittings and components used with conduits:

1. Conduit Fittings

Elbows (Bends): Allow changes in direction for conduit runs, available in various angles (e.g., 45°, 90°).

Couplings: Connect two sections of conduit to extend the length.

Connectors: Secure conduits to boxes or panels.

Adapters: Transition between different conduit types or sizes.

2. Conduit Supports

Straps and Clamps: Secure conduit to walls, ceilings, or structural frames.

Hangers: Support conduit runs, especially in overhead or long-span installations.

Bushings: Protect wires from sharp conduit edges, especially at terminations.

3. Boxes and Enclosures

Junction Boxes: House wire splices and connections safely.

Pull Boxes: Facilitate pulling cables through long conduit runs.

Outlet Boxes: Hold switches, receptacles, and devices.

4. Accessories for Special Conditions

Expansion Fittings: Allow thermal expansion in long conduit runs.

Weatherproof Covers: Protect outdoor or exposed installations from water and dust.

Sealing Fittings: Prevent moisture ingress in wet locations.

5. Custom Options

ULP offers OEM/ODM customization for fittings — including custom sizes, colors, logos, and packaging — so contractors and distributors can tailor conduit systems to specific project needs.

Why Choose ULP for Electrical Conduits and Fittings?

With over 15 years of experience, ULP is a one-stop solution provider for conduit systems. ULP advantages are:

● Comprehensive Product Range: UPVC, CPVC, HDPE, EMT, IMC conduits and fittings.

● High-Quality Manufacturing: Automated production in facilities over 10,000 m² with strict quality control.

● Customization Options: OEM/ODM for logo, color, size, and packaging.

● Competitive Pricing: Cost-effective without compromising quality.

● Professional Service: Dedicated technical and inspection teams for reliable delivery.

ULP ensures customers get more than products; they get a complete electrical conduit system solution for any project, whether residential, commercial, or industrial.

One-stop Pipeline and Fitting Manufacturer

FAQs: Know more about Electrical Conduit and Fittings

What is the difference between UPVC and CPVC electrical conduits?

UPVC (Unplasticized PVC) is rigid, corrosion-resistant, and cost-effective for general electrical wiring. CPVC (Chlorinated PVC) offers higher heat resistance and chemical stability, making it ideal for industrial environments or high-temperature applications.

Where is HDPE electrical conduit most commonly used?

HDPE (High-Density Polyethylene) conduits are widely used for underground electrical installations, telecom cable protection, and outdoor wiring due to their flexibility, impact resistance, and durability in harsh environments.

How do EMT and IMC conduits differ?

EMT (Electrical Metallic Tubing) is a thin-walled steel conduit suitable for indoor and commercial wiring where appearance matters. IMC (Intermediate Metal Conduit) is thicker and stronger, suitable for industrial and outdoor environments where mechanical protection is critical.

What accessories are essential for an electrical conduit system?

Key accessories include elbows, couplings, connectors, adapters, straps, clamps, hangers, bushings, junction boxes, pull boxes, outlet boxes, expansion fittings, weatherproof covers, and sealing fittings. These ensure safe installation and long-term performance.

How do I select the right type of conduit for my project?

Selecting the right conduit depends on factors like environment (indoor/outdoor), mechanical stress, temperature conditions, budget, and required lifespan. ULP's product range includes UPVC, CPVC, HDPE, EMT, and IMC conduits, covering virtually every application.

Why should I choose ULP for electrical conduit systems?

ULP is a trusted global provider of electrical conduit solutions with over 15 years of manufacturing experience. With a comprehensive product range, competitive pricing, advanced automation, strict quality control, and customization options, ULP offers reliable one-stop solutions for all conduit needs.

Can I customize electrical conduits and fittings from ULP?

Yes. ULP offers OEM/ODM services, including custom sizes, colors, logos, and packaging for all types of conduits and fittings—ensuring they meet specific project needs.

Conclusion

Choosing the right electrical conduit and accessories is vital for safety, durability, and efficiency. From the cost-effective UPVC to the robust IMC, each type serves unique needs. Combined with essential fittings like elbows, couplings, and junction boxes, a well-designed conduit system delivers long-term performance.

Partnering with ULP means getting access to a full range of high-quality conduit products and fittings—including UPVC, CPVC, HDPE, EMT, and IMC conduits and fittings—supported by customization and expert service. ULP is your trusted partner for comprehensive electrical conduit system solutions that meet international standards, project-specific requirements, and budget considerations. Click to know more about ULP.