Why Choose HDPE Steel Reinforced Thermoplastic Pipe (SRTP) for Water?

Categories:HDPE Pipe and Fitting Author: author

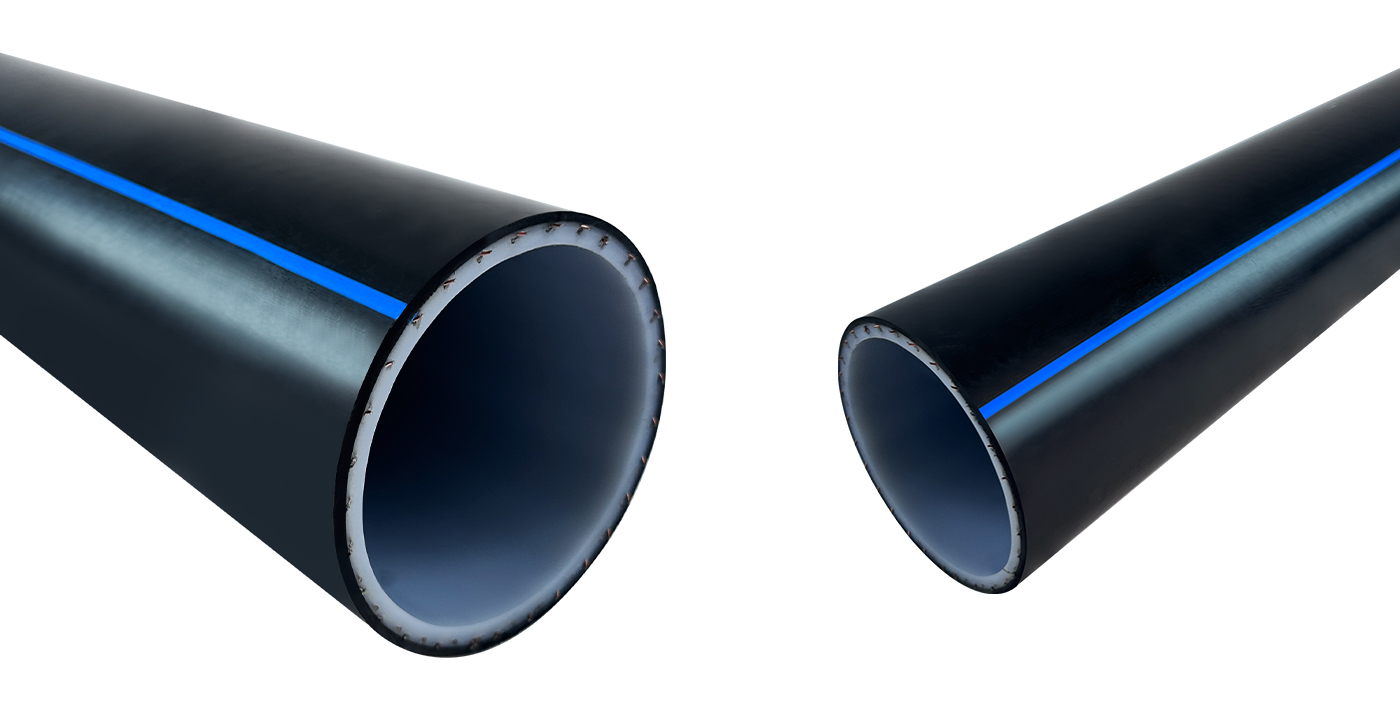

Urban water supply systems, agricultural irrigation projects, industrial facilities, and residential developments all depend on pipes that can withstand pressure, resist corrosion, and maintain consistent performance over decades. When it comes to building reliable and long-lasting water infrastructure, choosing the right piping material is crucial. One of the most advanced solutions available today is the HDPE Steel Reinforced Thermoplastic Pipe (SRTP). HDPE Steel Reinforced Thermoplastic Pipe for Water combines the strength of steel with the durability of HDPE, making it an excellent choice for modern infrastructure projects.

What Is HDPE Steel Reinforced Thermoplastic Pipe (SRTP)?

SRTP is an advanced type of pipeline that combines the strength of steel with the durability and flexibility of high-density polyethylene (HDPE). Unlike conventional pipes that rely on a single material, SRTP features:

● A steel reinforcement layer that provides exceptional strength against internal and external pressure.

● An HDPE pipe body that delivers excellent corrosion resistance, flexibility, and longevity.

● Protective black coloration to resist UV degradation when used above ground.

● Manufacturing standard compliance (GB/T 32439-2015), ensuring reliability and consistency.

This hybrid structure allows SRTP to deliver the mechanical performance of metal pipes while retaining the lightweight and non-corrosive benefits of thermoplastics.

PE Steel Reinforced Thermoplastic Polyethylene Composite Pipe for Water Supply (SRTP)

Why Choose HDPE Steel Reinforced Thermoplastic Pipe (SRTP) for Water Systems?

1. Strength and Durability That Outperforms Traditional Materials

Water systems demand pipes that can carry large volumes under pressure. Unlike conventional HDPE pipes, SRTP can withstand higher loads due to its steel reinforcement. Compared to ductile iron pipes, it is significantly lighter, making it easier to transport and install.

Key durability features include:

● Flame-resistant and corrosion-resistant: Ideal for environments exposed to chemicals, moisture, or extreme conditions.

● Rust & sunlight resistant: Unlike steel pipes, SRTP will not rust or degrade under UV exposure.

● Permanent printing: Ensures specifications and branding remain visible throughout the product’s lifespan.

This durability translates to lower maintenance costs and a longer service life, making SRTP a cost-effective option for large-scale water supply networks.

2. Wide Range of Applications

One of the reasons HDPE Steel Reinforced Thermoplastic Pipe is gaining popularity worldwide is its versatility. Its wide application range positions SRTP as a universal solution for modern water distribution. It can be used in both underground and above-ground construction, making it suitable for:

● Urban water supply systems: Delivering safe, clean drinking water to growing cities.

● Construction engineering: Reliable piping for large infrastructure projects.

● Agricultural irrigation: Durable pipelines that can handle heavy water flow across long distances.

● Industrial use: Transporting water or other non-corrosive liquids in factories and plants.

● Domestic water supply: A safe choice for residential projects where longevity and hygiene matter.

HDPE Steel Reinforced Thermoplastic Pipe for Water

3. Easy Installation and Cost Savings

Traditional piping systems often involve heavy machinery, lengthy installation times, and costly maintenance. SRTP, by contrast, is:

● Lightweight: Easier to transport, handle, and lay, even in remote areas.

● Compatible with electrofusion fittings: Ensures leak-proof joints that enhance the reliability of the entire water supply system.

● Low maintenance: Resistant to scaling, rust, and cracking, which reduces long-term operational costs.

For contractors and project managers, these benefits result in faster installation timelines and lower overall project costs.

4. Flexibility and Customization with ULP OEM/ODM Services

Every project has unique requirements, and ULP understands that flexibility is key. That’s why we provide OEM/ODM services with customization options, including:

● Size customization: Pipes available in different diameters and lengths to match project specifications.

● Color customization: Beyond the standard black, options for blue or other colors for easy identification.

● Packaging choices: Tailored solutions for safe transportation and efficient on-site use.

● Fittings compatibility: A full range of related fittings, including PE electric melting T-elbow, couplings, 90° elbows, and 45° elbows in both blue and black.

By offering these services, ULP ensures that you not only receive high-quality pipes but also a complete one-stop solution for plastic pipeline systems.

Comparing SRTP with Traditional Pipe Materials

● PVC pipes: Lightweight and cheap, but less durable under pressure and prone to cracking.

● Ductile iron pipes: Strong but extremely heavy, costly to transport, and susceptible to corrosion.

● Concrete pipes: Durable but difficult to install, requiring heavy machinery.

● Standard HDPE pipes: Flexible and corrosion-resistant, but not strong enough for high-pressure applications.

SRTP combines the advantages of each material while avoiding its weaknesses. It is strong yet lightweight, resistant to both corrosion and UV, and easier to install than heavy materials.

Why Choose ULP as Your Pipeline Partner?

There are many pipe manufacturers in the market, but what sets ULP apart is its commitment to quality, service, and innovation.

● Over 15 years of manufacturing expertise in pipes and fittings.

● OEM/ODM customization services, including size, color, logo, and packaging.

● Comprehensive fittings supply for complete one-stop solutions.

● Competitive pricing without compromising product standards.

● Global reputation as a trusted pipeline system solutions provider.

● Customer-first approach with responsive support and after-sales service.

● Samples available to test product suitability before large-scale deployment.

By partnering with ULP, you gain more than just a supplier—they gain a reliable partner for long-term infrastructure success.

HDPE SRTP Pipeline System Solutions

Conclusion

The success of any water infrastructure project depends heavily on the reliability of its pipeline system. The HDPE Steel Reinforced Thermoplastic Pipe (SRTP) stands out with its hybrid design, durability, resistance to corrosion, and long-term cost savings. With wide applications across urban, industrial, agricultural, and domestic projects, it is becoming the go-to solution for modern infrastructure.

By choosing ULP, you not only get access to premium SRTP pipes and fittings but also benefit from customized OEM/ODM services, competitive prices, and the assurance of working with a globally trusted pipeline solutions provider. For anyone seeking a one-stop solution for plastic pipes and fittings, ULP is the name to trust. Browse our HDPE SRTP for water systems or contact us for more.